Yeah, it changes without skipping a beat for me in pipewire, even in things like zoom/teams.

Yeah, it changes without skipping a beat for me in pipewire, even in things like zoom/teams.

I use a little oneliner with tofi (rofi/wofi would also work) to select the current output and avoid pavucontrol. It’s mapped to a sway binding but would probably work in any wm/de:

pactl set-default-sink $(pactl list short sinks |awk '{print $2}' |tofi $tofi_args)

I’m using pipewire so the functionality of pactl is actually provided through pipewire-pulse I think

This gave me an idea. Have you considered buying a used higher quality rack and modifying it? Might save some time and get you what you want with less new material, and sort out some of the harder parts to fabricate because they’d be done already, possibly only requiring a little bending to align with your eyelets. Plus you’d be saving something from someone else’s scrap pile.

Around me there are a few community run used bike part shops. They typically have lots of racks and other parts kindof organized into piles or boxes by type. I can usually find something close to what I need if it’s not too specific.

I’m not aware of a welding process that is safe for humans without at least a dust/fume extractor. That and a respirator with the appropriate filters for the application that fits under a welding hood is basically standard equipment even for hobby welding in my opinion. Also hex chrome is a particulate, not a gas, and tig welding uses solid rods (not flux core) and a much smaller heat affected zone so it’s already better in that area AFAICT, but I’m not an expert in this area.

As far as particulates when welding go you should watch how careless people are when they grind their tungsten electrodes containing all kinds of dangerous additives with their respirator around their neck because “I’m not welding so I don’t need it”.

So yes, this is good advice. We should all think more about the things we do, even when working on home improvement projects and mundane stuff, that could end up damaging our lungs.

If you want it to be easily repairable (you mentioned this in another comment) I’d go with small diameter aluminum tube and a very very good radius bender if you can AC tig weld, or stainless steel (maybe 316?) if you can only do DC tig. The reason for this is because neither option “requires” paint, though the aluminum does benefit a little from paint. Paint makes everything harder to repair (assuming the repair involves a welding process) because you have to grind it off again if you break something or want to make a modification.

Also, I totally get wanting to make things. My hobby projects are normally zero percent about saving money and 100% about having fun. Most things I make in my shop would cost about 1/4 of the price if I just went to the store and bought them, especially factoring in time and consumables.

EDIT: I suppose this comment really gives away what region I live in lol

Gatgetbridge (your link) has a breakdown of devices they support https://gadgetbridge.org/gadgets/ . You can click through the vendors to find devices which are both “highly supported” and “no vendor-pair”. Meaning most/all the features work without any reliance on the vendor app.

As for the similarity you are asking about with pixel->GrapheneOS, there are very few watches that can run an alternative open source firmware or operating systems apart from the ones that are already open source, like bangle.js, pinetime, etc. Wearables are even more specialized than phones, they require specialized code designed specifically for them and would likely require pretty extreme effort to reverse-engineer.

I use a pebble 2 HR with gadgetbridge but the watch it self runs the old pebble firmware which gadgetbridge talks to. This is fine for me, but if you are looking for a more modern watch you may have to make some compromises.

What makes those methods better?

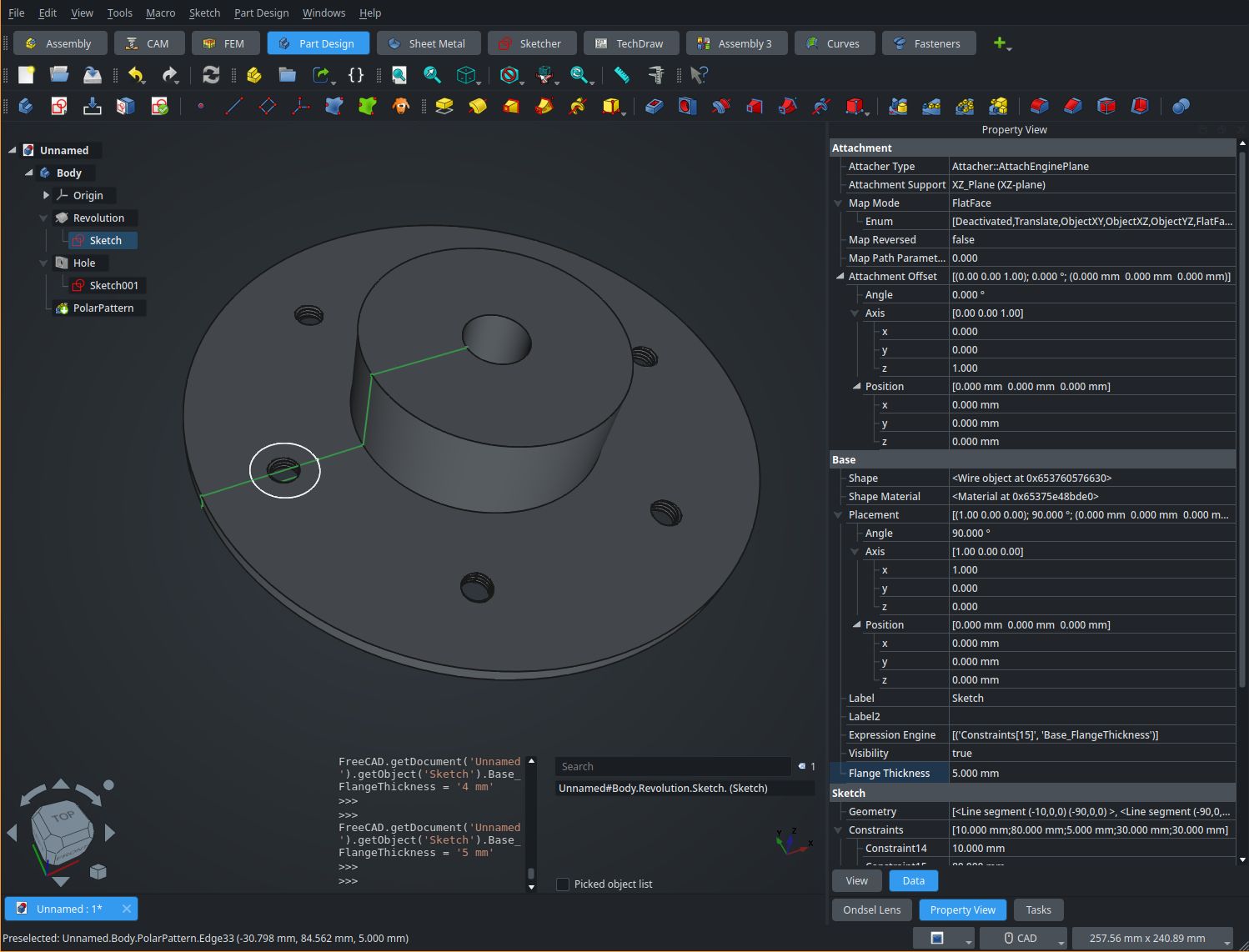

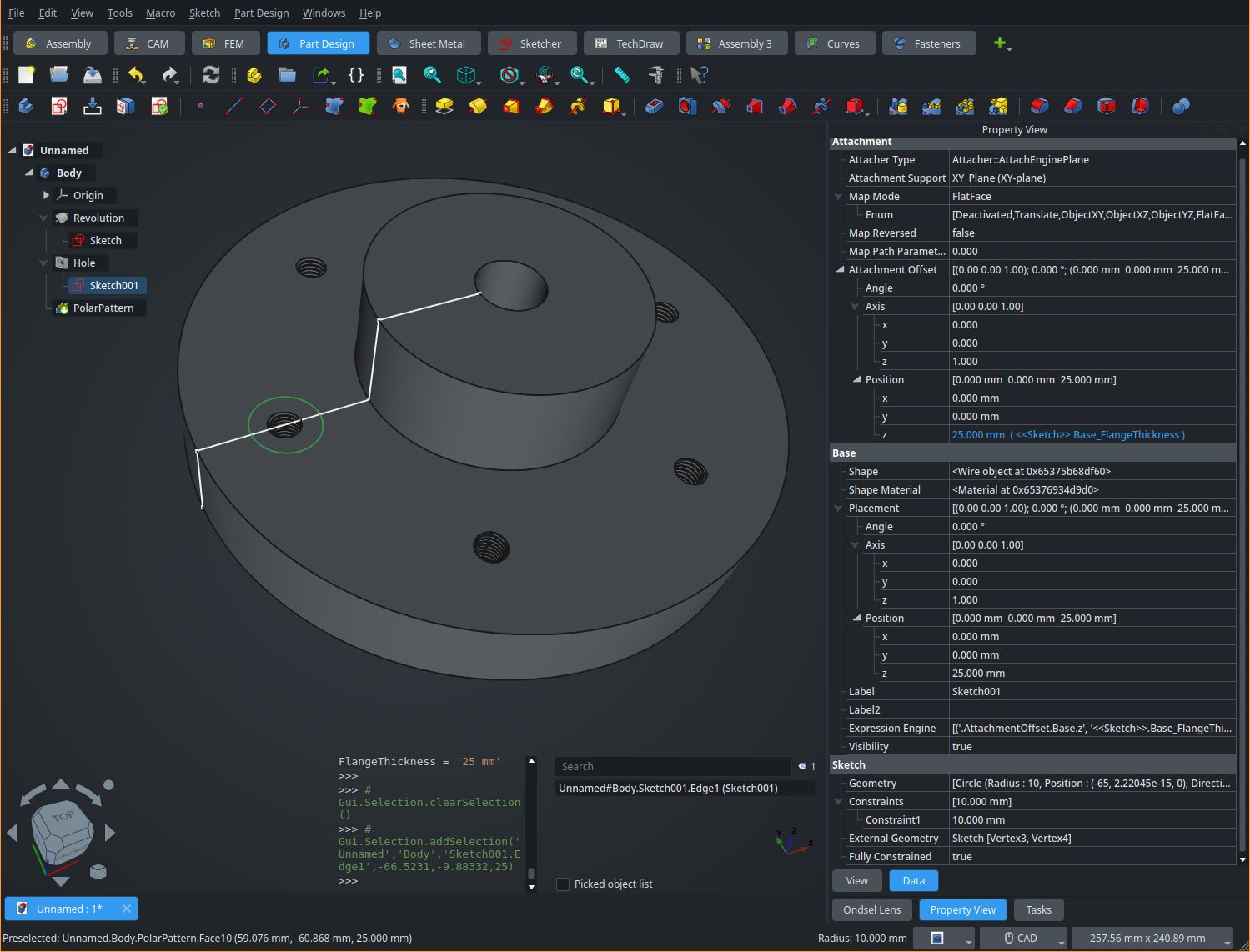

Disclaimer, I’m at a sortof “advanced hobbyist” level of cad. My understanding of the topological naming problem in general is that it exists in all cad because it is a sortof byproduct of how computers keep track of data about 3 dimensional objects. If you make a cube, all the sides need to have an identifier associated with them. If you put a hole in that cube, you now have more identifiers and have to decide what ordering makes sense. It sounds easy to work around with a cube but when models get really complex it’s not so easy, especially when you change something way back at the beginning which creates more or less faces in the middle of the list somewhere.

Freecad isn’t making the topological naming problem “go away”. They are creating (or rather merging, it’s been around a long time) an algorithm that makes a better guess at what the order should be, rather than sticking new faces in the list and reordering without any consideration of what happened after that face was created. This is, as far as I understand, also how other CAD packages do it, and you can still back yourself into a topological naming problem if you try hard enough (or don’t try at all I guess) in both freecad with the new changes applied, and in other CAD packages.

So “best practice” is to be smart about the attachment of your geometry thinking about how things might change in the future, rather than clicking the closest face whenever you need a sketch plane. In reality modern proprietary cad is so good at guessing and maintaining consistency that it doesn’t matter unless your model is horrendously complex and whoever made it didn’t pay any attention to laying out the base sketches in an organized way.

For example if you make a flange but you’re not quite sure about the thickness, base the sketch for say, the holes, on the parallel origin and offset it by the height of the pad or the length of the sketched geometry. Or use a spreadsheet or variableset for the value of both the thing that you define the thickness with, and the offset from the origin plane. That way if the value changes, nothing will break.

I made a test model but it isn’t something that shows up well in a single screenshot unfortunately. See the “Flange Thickness” and z offset parameters in the property view. I used that for the flange dimensions, and the hole sketch offset.

Interesting, it is working for me in wayland and the drop down menus are fine but I’m using sway which is a totally different wayland implementation than what KDE is doing. I’m glad you found a workaround.

Unfortunately I don’t know what is causing the exact issue you are having, however here are a few things I found when doing this myself that are “gotchas” (not immediately obvious).

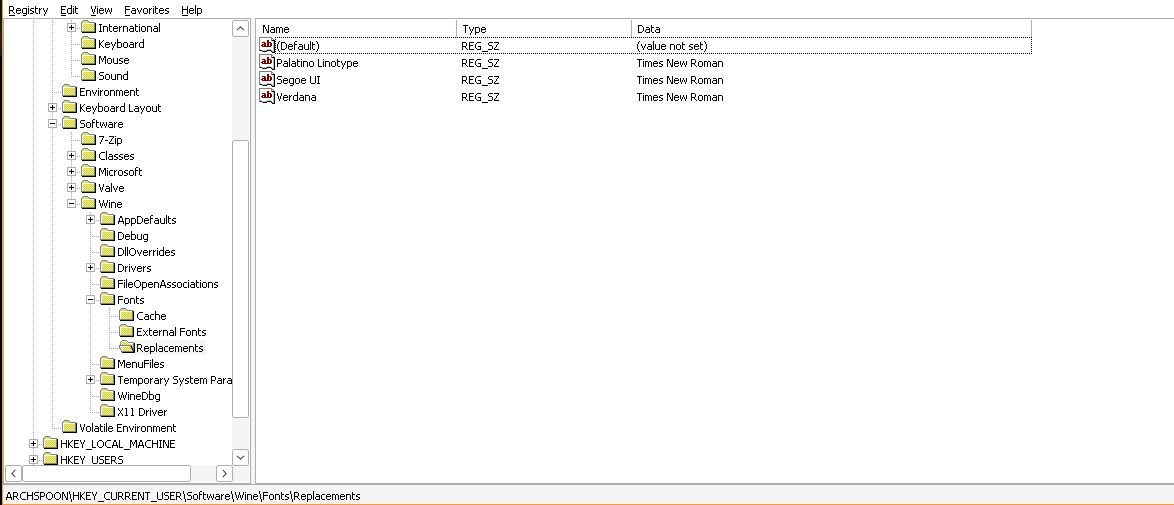

This is the reason your fonts are all Times New Roman. Go to that key using protontricks regedit and delete all the font replacements.

Anything you put in $HOME/.steam/root/steamapps/common/assettocorsa stays there, even if you uninstall the game. If you want to “start over” you have to uninstall the game and then delete the whole assettocorsa directory there, and the wine prefix in $HOME/.steam/root/steamapps/compatdata/244210

AC and content manager work without .net changes in the latest GE but you do need corefonts which you can install with protontricks. If you want to be extra sure you have the right .net you can install dotnet472 but I don’t believe this is necessary anymore as it will be installed automatically or is already installed. You may get a wine .net error the first time you launch the game but it’s only the first time.

If you choose to use CSP you have to unzip the archive you get from either Patreon or acstuff.ru and manually copy the dwrite.dll file into $HOME/.steam/root/steamapps/common/assettocorsa on EVERY upgrade. The zip installer built into CM doesn’t do this correctly on Linux. It will cause rain not to work if you choose to use the Patreon version if you don’t do this manual step.

I think you should start over and make sure the assettocorsa directory is clean before re-installing the game. It could be missing fonts, but it’s hard to say. You can back it up somewhere if you have data in there you need.

I like tofi as a wayland alternative. Unfortunately like so many of these projects it seems to be somewhat recently unmaintained.

Does Bazzite use a gamescope session on wayland by default? Gamescope has a bug which prevents the wayland client from drawing the steam overlay. I suppose it’s unlikely to be the same issue but I happen to be dealing with it on my system (not Bazzite) so I immediately made the connection.

AOSP gallery that comes with GrapheneOS. The app info says it’s called com.android.gallery3d. There’s some info here in the docs about the relationship between camera, edit functions, and the gallery app.

No, I don’t have markup installed (it is there in apps but not installed from the mirror).

I think in my case the screenshot functionality is built into AOSP and the editor you get when tapping the resulting preview overlay in the lower left corner of the screen is part of the “gallery” app since using the “edit” feature from gallery launches the same editor. Maybe GrapheneOS just sets that as the default editor, I’m not sure.

What android OS do you use? On stock Android 14 (GrapheneOS, but it’s not a GOS feature) this functionality is built into the stock screenshot tool.

pwr+voldown -> tap screenshot that appears in the overlay after you take it -> tap the crop tool . I suppose step three could be removed but what if you want to do something that isn’t cropping? There are lots of other features so at some point you have to tell the tool what you want to do.

broad support for generic smart watches

Gadgetbridge is pretty well on it’s way to this. They roll out support for new devices monthly it seems like. Of course there are always feature X and Y that fitbit or garmin does that it doesn’t, but it’s quite an impressive project. I use it with a pebble 2 HR.

What version of kde? I haven’t tried it, or read about it beyond the changelog, however the latest beta release says that it supports RDP to connect to plasma desktops which is quite an interesting development if it works the way it sounds like it does:

Remote Desktop system integration to allow RDP clients to connect to Plasma desktops, plus a new page in System Settings for configuring this

For the “from anywhere” component you could use a vpn, but if you’re looking for a simple solution with zero configuration than nomachine or rustdesk seem more appropriate. Just thought the RDP support was worth sharing.

Memories and Gallery (actually deprecated by photos) are not the same thing, just to clarify. I’m not in a position to agree or disagree with any of the statements here since I’ve never used immich, but I don’t want people to think that the default photo viewer in nextcloud is what was being discussed here.

If you want to monitor sleep with it charging at night isn’t possible, and remembering to charge every single day during the day is annoying in my opinion. Not everyone wants sleep monitoring though, or likes to sleep with a watch on, so I get why there’s some division on the subject.

My pebble 2 hr lasts about 5 days and I’m very happy with that frequency of charging. I think it was a bit better when new but that was a long time ago.

So, I’m not sure if the process has changed in the last decade or so but in a long-ago computer forensics class step 0, before all else, was to never operate data recovery on the original disk. Create a block level image of the entire device, then work on that.

My go to steps for recovery have been the following in the years since:

ddrescue -d /dev/sdX <path_to_image>.imgtestdisk <path_to_image>.imgIf the disk has a complicated partition layout, or more effort is required to find the correct partition you can also mount parts of the disk.

create an image of the entire disk (not a partition) using ddrescue

ddrescue -d /dev/sdX <path_to_image>.img

Mount the image as a loopback device with the appropriate offset

losetup --offset <some_offset_like_8192> --show -v -r -f -P <path_to_image>.img

this will mount individual partitions:

loop58 7:58 0 465.8G 1 loop

├─loop58p1 259:7 0 1.5G 1 part

├─loop58p2 259:8 0 450.6G 1 part

└─loop58p3 259:9 0 13.7G 1 part

Then operate testdisk on whatever partition you want.

All that said there are a lot of variables here and things don’t always work perfectly. I hope you do find a way to recover them.

Or add EA anti-cheat 6 months after release like they did for EA WRC.