I have this incredibly loud noise coming from my Y-axis. It doesn’t affect print quality, but it is horrible to listen to and really loud. It is present when the Y-axis moves at ~100mm/s and gets worse/louder as speed increases.

How can I mitigate this? There doesn’t seem to be any mechanical issues when I move the bed by hand, it is smooth and easy to move.

If you can, put your finger on safe to touch spots, to see if you can find where that vibration is coming from. Start with the stepper motor, or even the bed itself. (Be safe, don’t heat the bed). Super Light pressure should be able to feel vibrations, heavier pressure might temporarily make the noise stop, giving you hints at what is actually wrong.

I’ve tried putting a hand on the stepper, it doesn’t really reduce the noise. Its a bit hard to keep a hand on the bed when it’s moving at high speeds though. I’ll see what I can make work.

Pretty sure it’s some sort of motor vibration that hits a resonance frequency in the frame/chassis/bed of the printer.

Moving the bed through its full RoM by hand slowly, do you feel constant resistance? Is your motor even slightly loose? That can definitely amplify any motor noise. It’s probably worth lubricating your rails, I’m assuming you have something like a creality cr10? Here’s creality’s wiki for maintenance. White lithium grease in a syringe is my general use for printers, I do like 3-in-1 or another light oil for my Mk3s though, really easy to apply a light coat to the guide rods

I’ve suspected resonance in my z axis on my bed slinger, only shows up with large moves and higher ambient temps, and the sound is best described as a way louder stepper noise.

Moving the bed through its full RoM by hand slowly, do you feel constant resistance?

Yes, it feels smooth without noticeable differences in resistance.

Is your motor even slightly loose?

It was when I received it, but I tightened it. I will definitely give them a look again, they might have come loose.

I’m assuming you have something like a creality cr10?

Yes, anycubic Kobra 2, but they are mechanically very similar. I’ve already greased rails with lithium grease, that was the first thing I did.

the sound is best described as a way louder stepper noise.

Yes it does kind of sound like excessive step noise. But I can actually feel the vibration in the printer, and even the table it’s standing on.

I’d check the bearings too.

My Anycubic does the same and i read from more people having this problem. You can losen the tension of the belt with the red screw infront of the printer. This fixed it for me.

Hmm…the belt is already pretty loose, but I guess I can give it a shot

Maybe too loose? Should be tightened completely and then one 360 degree turn

New Lemmy Post: Loud noise coming from Y-axis (https://lemmy.world/post/11204456)

Tagging: #3dprinting(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md

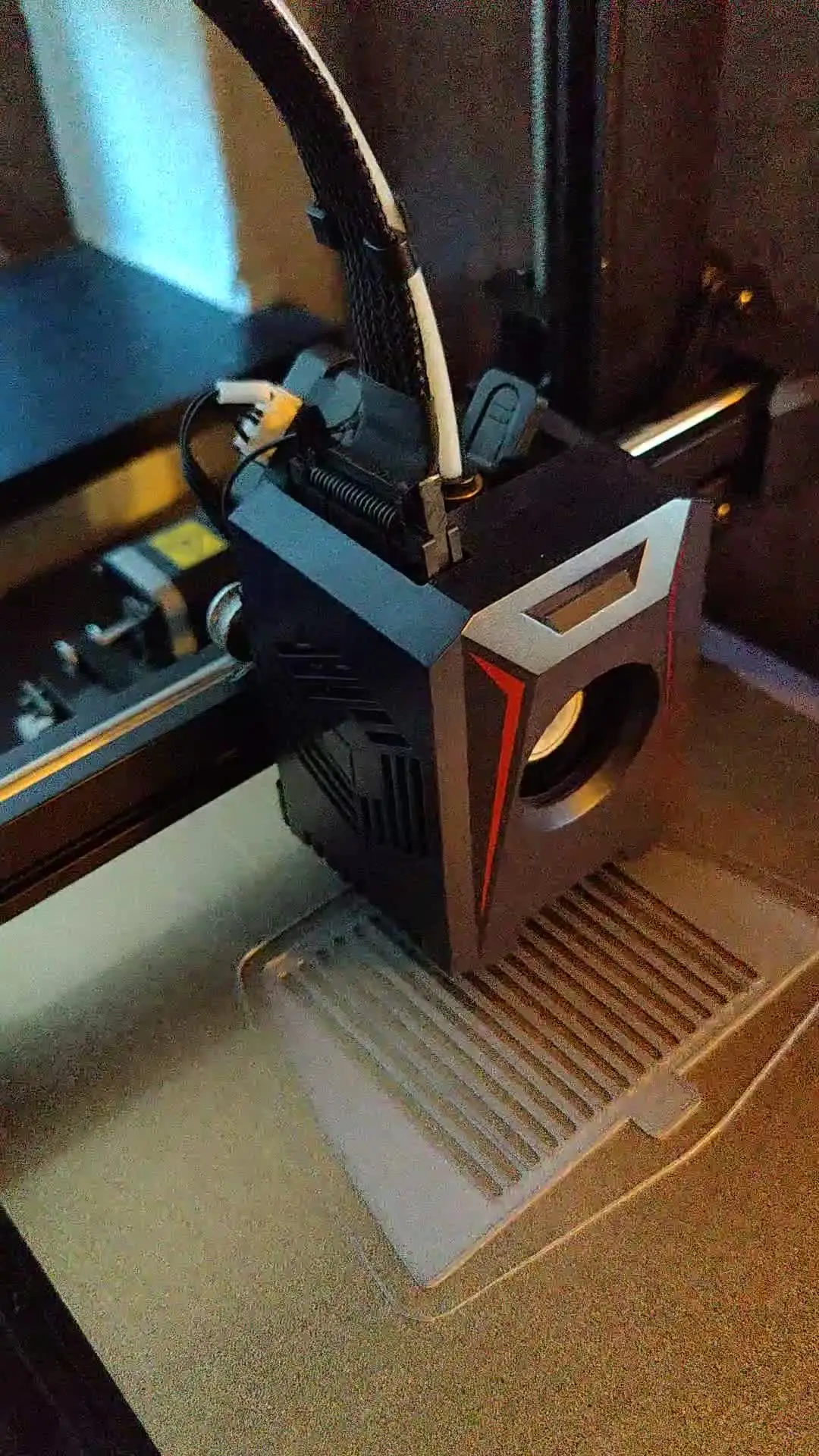

I did a lot more testing to locate the source of the sound today.

Like I suspected, it was related to the motor for the Y-axis driving the bed back and forth.

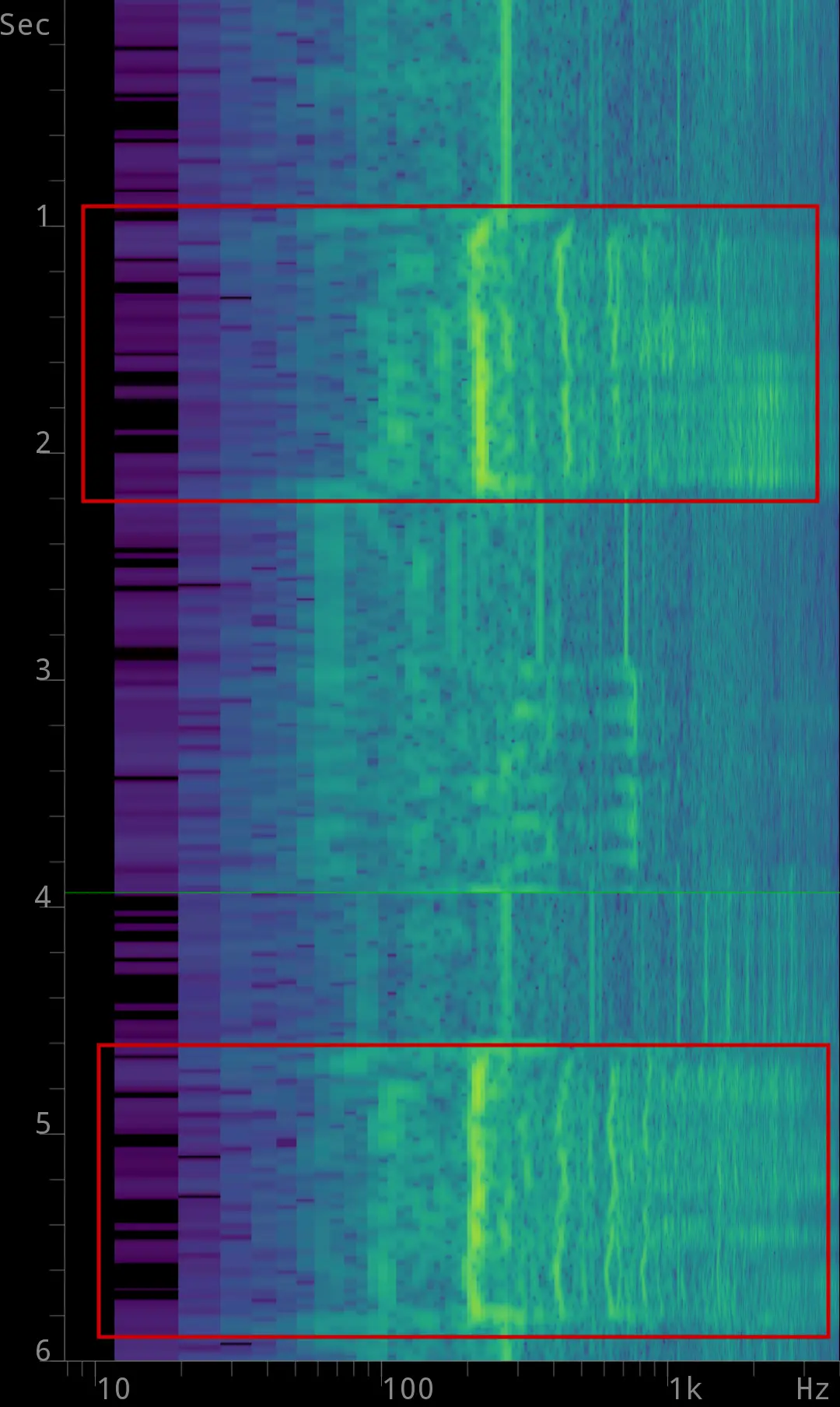

I made a small test macro that moves the bed back and forth a few times and a fixed speed, with max acceleration. The areas marked with red squares in the images below is when it was moving the Y-axis alone on full speed (175mm/s in the test)

I did some light frequency analysis to see which frequencies were actually the issue, and the excessive noise seems to be around 200Hz.

Loudness of this is somewhat affected by the tightness of the belt, but not in a significant way. But even with the belt and bed disconnected from the motor, the sound remains almost unchanged in loudness.

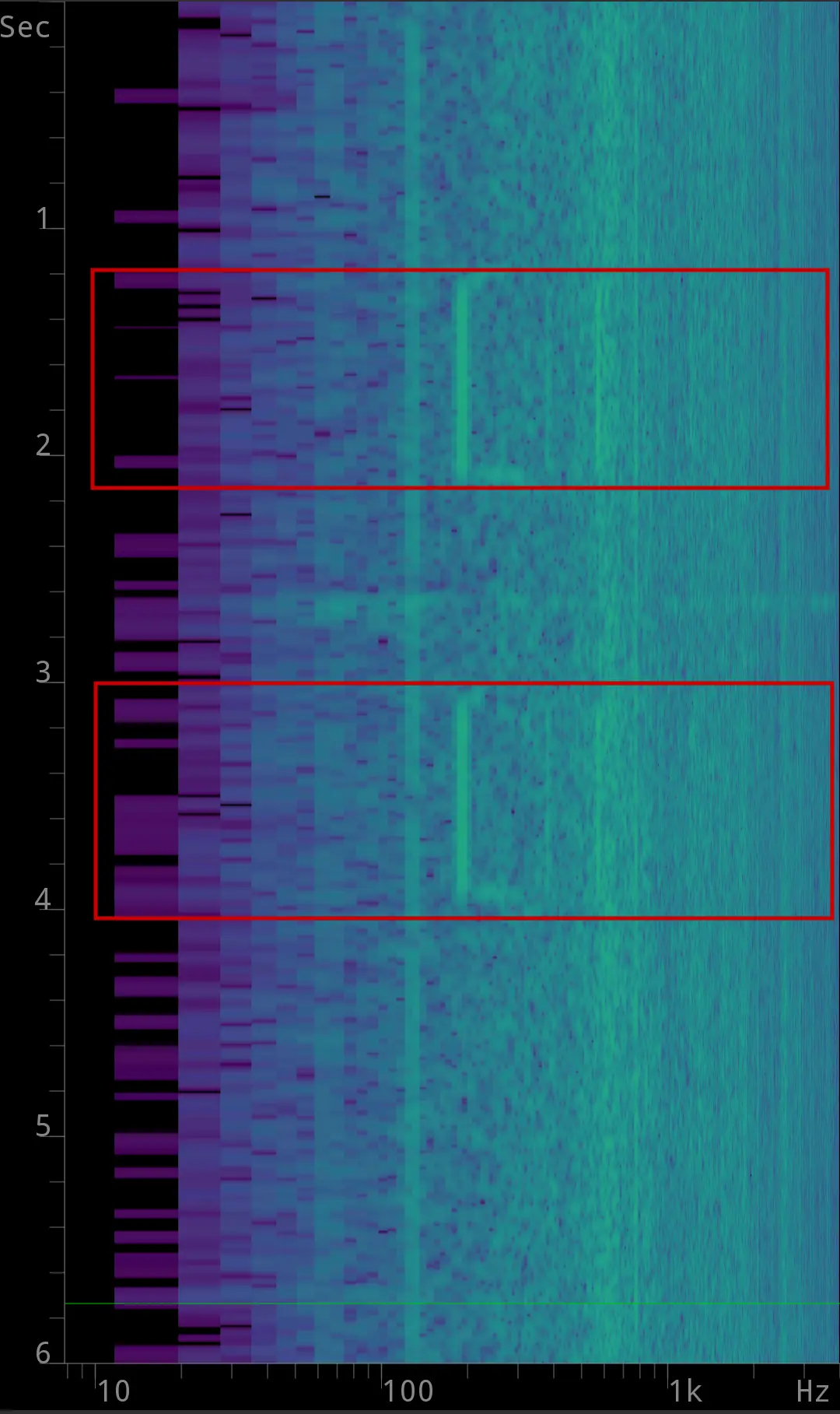

I unmounted the Y-axis motor from the frame and printer and placed it on a vibration-dampening mat and performed the same test again.

It clearly shows the 200Hz sound is originating in the stepper, red boxes in the image above mark the Y-axis movement. It shows the vibrations at approx. 200Hz, but at a much lower level.

so it would seem that it is more or less the frame that amplifies the motor vibration to an excessively audible level.

Next step in this is going attempting to mechanically disconnect the motor from the frame with some dampeners and rubber washers and see if that will help significantly.